Product cate

By shape

By purpose

Project Introduction

FFS film Description:

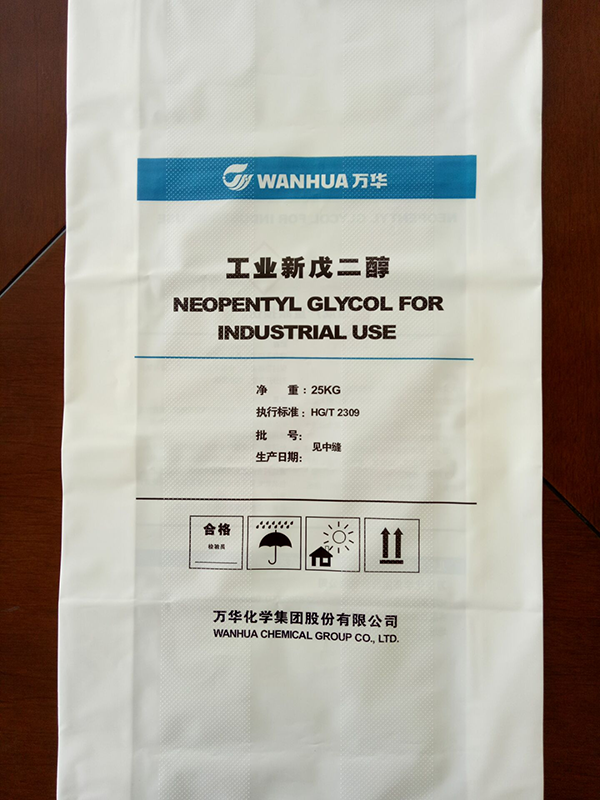

FFS films (also called heavy duty bags), are made of virgin PE (HDPE,LDPE,LLDPE)and high quality additives with 3-lay coextrusion blown film, 6-color high speed printing and computer controlled sealing bottom. Forming, filling and sealing are carried out on one automatic packaging machine. Which are mainly used in the packaging of pretrochemical granular and other prowdery solid products.Due to its easy recycling,conformation to the international general fouth environmental protection packaging material requirements and other unique advantages of automatic packaging, storge,shipping,moisture-proof,good appearance,ect, it has become a popular packaging soluction in Europe and other delevoped countries. It is also becoming a tried-and-tested alternatvie packaging soluction to domestic petrochemical industry and gradully replacing the tradditional plastic woven bags. As expected, it will be the main products in the heavy duty packaging industry.

Anti-skid heavy duty bag is made through special process embossing treatment forming two prominent slippery band and result in an effective anti-skip effect. Meanwhile, it appears very well through heat sealing and punching at the four corners during the storage of stacking.

Product Features:

1.It meets the requirements of high strength, high temperature-resistance, anit-dropping, anti-crocking,ect with three-lay coextrusion and unique material ratio during the high speed filling, transmission and stacking.

1.It meets the requirements of high strength, high temperature-resistance, anit-dropping, anti-crocking,ect with three-lay coextrusion and unique material ratio during the high speed filling, transmission and stacking.

2.Anti-ultraviolet, color stability ,no deformation at high temperature, no crack at low temperature, it can save the storage space and entend the shelf life more than one time compared with woven bag.

3.sealing, moisture resistance, superior water-proof and antifouling performance, can open piled up, easy to transport and storage, inner product does not melt or agglomeration, won’t break quantity or quality loss;

4.it is fully suitable for high-speed packaging machine and can reach more than 1,800 bags per hour. the efficiency of packaging improves 3-5 times and save about 75% labor cost compared with traditional packaging

5.with the application of new materials, the film thickness gradually reduces, the strength gradually increases, the overall cost of packaging is better than the traditional packaging % or so

6.the application of new raw materials (LLDPE, LDPE, HDPE, etc.) and quality additives to ensure reliable film quality . packing bag easily recycled and processing, protect the ecological

7.to solve the problem of warehousing, higher stacking, storage space savings, but also lower than the traditional woven bag packaging costs;

According to the demands, we imported 2 world’s most advanced three-layer coextrusion film blown production lines from Costruzioni Meccaniche Luigi Bandera S.P.A ,Italy in 2013 and 2 worlds most advanced three-layer coextrusion film blown production lines from Reifenhauser Blown Film GmbH,Germany in 2016. Two sets of integrated machines with side gusset making, embossing,flexo pringting and one set of bag making machine. The annual output reached the 10000 tons as of the end of 2016. Our planned annual production capacity will reach increase yearly. At the same time, we introduced the advanced testing and inspection equipments such as friction coefficient, falling dart tester,rally tester,high & low temperaturer tester,melt index detector,heat sealing apparatus and other testing devices. Good products are from high quality raw materials and skilled production process. So, we also pay high attention to the top brand raw materials. "To supply customers with first-class products and first-class service" is our company's quality policy, we strictly implement the ISO9001: 2008 quality management standard, ISO14001: 2004 environmental management standard and obtained OHSAS18001: 2007 occupational health and safety system certification, BRC quality system certification, Sedex certified members. Our company strictly implement the ISO9001: 2008 quality management standard as a long-term strategic decision, adhere to management innovation, "6S" management, full participation, and strengthen internal management. Focus on the shaping of modern enterprise image and the accumulation of intangible assets, promote the spirit of teamwork, advocate the "customer first, survival on quality, innovation and development", take any opportunity to expand domestic and foreign markets and strive for the top brand.

According to the demands, we imported 2 world’s most advanced three-layer coextrusion film blown production lines from Costruzioni Meccaniche Luigi Bandera S.P.A ,Italy in 2013 and 2 worlds most advanced three-layer coextrusion film blown production lines from Reifenhauser Blown Film GmbH,Germany in 2016. Two sets of integrated machines with side gusset making, embossing,flexo pringting and one set of bag making machine. The annual output reached the 10000 tons as of the end of 2016. Our planned annual production capacity will reach increase yearly. At the same time, we introduced the advanced testing and inspection equipments such as friction coefficient, falling dart tester,rally tester,high & low temperaturer tester,melt index detector,heat sealing apparatus and other testing devices. Good products are from high quality raw materials and skilled production process. So, we also pay high attention to the top brand raw materials. "To supply customers with first-class products and first-class service" is our company's quality policy, we strictly implement the ISO9001: 2008 quality management standard, ISO14001: 2004 environmental management standard and obtained OHSAS18001: 2007 occupational health and safety system certification, BRC quality system certification, Sedex certified members. Our company strictly implement the ISO9001: 2008 quality management standard as a long-term strategic decision, adhere to management innovation, "6S" management, full participation, and strengthen internal management. Focus on the shaping of modern enterprise image and the accumulation of intangible assets, promote the spirit of teamwork, advocate the "customer first, survival on quality, innovation and development", take any opportunity to expand domestic and foreign markets and strive for the top brand.

Partner

Montana coal

Inner Mongolia Mengda New Energy and Chemical Co., Ltd. (CMMD) is the second-tier enterprise under the China Coal Group and is responsible for the management of 600,000 tons of methanol project invested and constructed by China Coal Group in Erdos region. Annual production of 600,000 tons of olefin project. With an annual output of 600,000 tons of olefin project in the Ordos Group in the investment and construction of key projects, but also industrial development in the Ordos demonstration project. Plant covers an area of 197 hectares, the estimated total investment of 10.636 billion yuan. The project uses the international advanced DMTO technology, extending the development of downstream products of methanol, the main products are 300,000 tons / year of polyethylene, 300,000 tons / year of polypropylene and C4, MTBE and so on.

Yangtze River Petrochemical

Zhangjiagang Yangtze River Petrochemical Co., Ltd., Jiangsu Feixiang Chemical Co., Ltd., Jiangsu Huachang Chemical Co., Ltd. and Donghua Energy Co., Ltd. and other three units jointly funded the establishment of enterprises. Of which: Tung Wah Group of Energy invested 56%, Flying Chemical and Huachang Chemical 22% of the capital. The establishment of three joint ventures Yangtze River Petrochemical, is conducive to give full play to their advantages, the formation of good synergies. Yangtze River Petrochemical is located in Zhangjiagang, Jiangsu Yangtze River International Chemical Industrial Park, close to the company Zhangjiagang reservoir area, the registered capital of 1 billion yuan. Yangzi Petrochemical's main investment target for the 60 × 2 million tons / year propane dehydrogenation project, and a 400,000 tons / year of polypropylene project.

Total Petrochemicals

Total Petrochemical (Ningbo) Co., Ltd. Is a wholly owned subsidiary of Total Group. It is a new - generation FlNA bulk polymerization process with an international advanced level. The annual output is 200,000 tons of polystyrene (HlPS). Total is one of the world's largest integrated oil and gas companies with a refining and petrochemical business, including specialty chemicals, refining and petrochemicals, and a global workforce of 50,000, with 13 refineries, 21 petrochemical production bases and over 150 specialty chemical and fertilizer bases.

Luxi Chemical Industry

Luxi Group was established in 1992, is the original Luxi Fertilizer Plant (1976 construction) on the basis of the progressive development of the state-owned holding enterprise groups, in May 1998 initiated the establishment of Luxi Chemical Group Co., Ltd. in Shenzhen Stock Exchange Listed. Group currently total assets of 25.8 billion yuan, more than 13,000 employees.Customer Testimonials

Montana coal

We are a subsidiary of the central enterprise of China Coal Group, which is responsible for managing 600,000 tons of methanol project and 600,000 tons of olefin project invested and constructed by China Coal Group in Erdos area. Our cooperation with the big day from the tender, was also a large number of days of the cooperation of the unit had some visits, since the cooperation, the big products in use did not appear before we have suppliers M side Not open phenomenon, M edge rupture phenomenon, sealing temperature fluctuations and so on. Days at low prices, stable quality, on-time delivery, good service really won our confidence and affirmation, let us feel that is really a big business to the heart of the big companies!

Tung Wah Group of Energy

Our cooperation with the big day from other companies recommended in the supply for more than 10 years, based on the day never had a serious quality accident, but also for us to solve some problems, in August last year , Then there have been bad sealing packaging, when we agreed here is the packaging of product quality problems, and then we informed the big companies, the morning of notice, the company's technical staff at the big day to the scene, after the scene view Finally found that the packaging machine temperature control system damage, the system shows the temperature with the actual temperature is not the same as sealing the bad phenomenon, after this one thing, let us really feel that the big is a technology-based, and To have a good after-sales service to win our confidence and affirmation, let us feel that is a big intention to run a large company!

Total Petrochemicals

Total Petrochemicals is one of the world's largest oil and gas integration companies, the requirements of suppliers is very strict, FFS film requirements are very thin, but also to ensure that 6m wrestling package is not broken. The technical requirements are higher than industry standards. [Due to the introduction of the international advanced Italian Bondra blown film (12 wire-23 wire) by Anhui Tianda, the printing production line, advanced testing equipment, professional technicians and perfect after-sale service system can meet the high quality requirements. After a number of tests and screening, we finally chose Anhui Tianda. ]

Luxi Chemical Industry

Contact Anhui Tianda from their packaging products in the industry a good reputation; February 20, 2014, we urgently need new products FFS film 10 tons test machine; we found the Anhui Environmental Protection New Material Co., Ltd.-day sales Director of Lv Zhengbao, to negotiate the procurement of FFS re-packaging film; FFS products because we are the first contact, the technical situation do not understand, Anhui Tianda arrange production, technology and sales together to communicate with us face to face, we are very satisfied! More importantly, because of our procurement application approval time delay, leading to the procurement cycle to arrive within 3 days, Anhui days of night driving system and delivered to our company on time, our various departments have put up a thumb! Laid the foundation for our long-term cooperation!Customization process

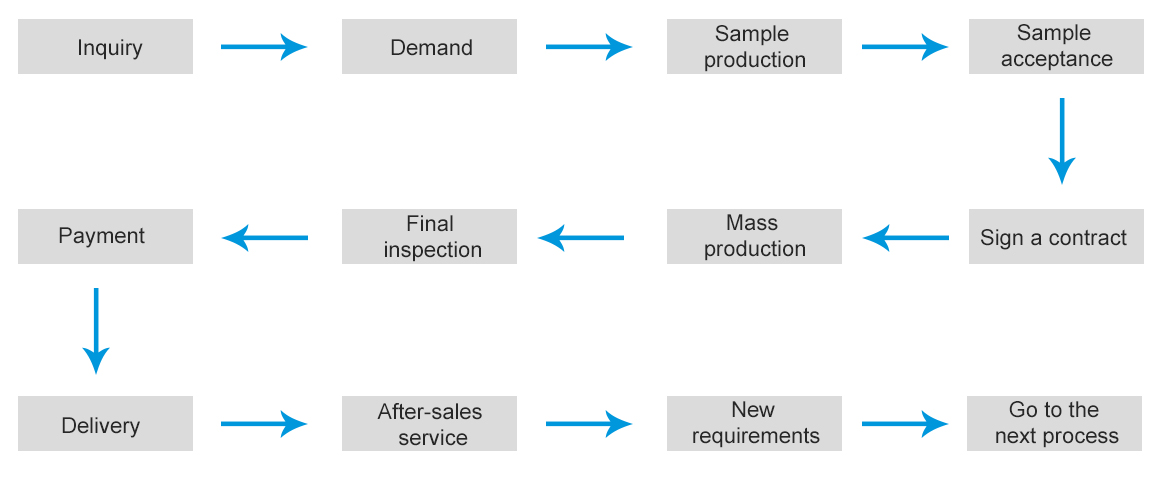

Customer consultation

- Do you have any suggestions for FFS film layout design?

- The advantage of FFS film is its fast packaging speed. In view of this advantage, it is required that the printing layout of FFS film be a circular layout. On the basis of the circular layout, it is necessary to meet the requirements for printing aesthetics on the one hand, and on the other hand, it is also necessary to meet the production needs of the printing machine. The design of the fixed layout should be simple and clear. If you have any questions, please consult our relevant personnel in detail.

- What is the film surface resistance of FFS film that can meet the requirements of mutual friction between film surfaces without generating static electricity?

- If the film surface friction does not generate static electricity, the film surface resistivity should be at least 10 to the 9th power ohm.

- What are the uses and characteristics of cold-drawn stretch film?

- The cold-stretched casing film is applicable to the packaging film of products such as petrochemical, household appliances, building materials, bottle filling and other products. It has excellent resilience, high clamping force to ensure stable load, excellent toughness, puncture resistance and resistance, good transparency, and can maintain efficient performance under high and low temperature environment.

- What standard can your FFS film fall test meet?

- Our FFS film bag dropping test is superior to the industry standard. If there are special requirements, our company can adjust the formula to meet the front height of 6 meters.

- Is your FFS heavy enough to drill holes, and will the strength of the bag be affected after drilling holes?

- Microholes can be drilled without affecting the strength of the bag. Our equipment is equipped with advanced microporous device, with flexible specifications. Our formula is unique, and the bag will not break after punching.

- At present, how to solve the problem of loose stacking after stacking with FFS film packaging?

- On the one hand, it can be solved by adjusting the equipment. If the equipment fails to solve the looseness, the film manufacturer can improve the friction of the packaging film.

- What is your suggestion on the roll diameter of FFS film?

- The size of the FFS film roll core is as large as possible when the packaging equipment can meet the requirements. This can save manual work and reduce the roll change time of the film roll. At present, the roll diameter of mainstream equipment in China is normally about 1.35 meters, which is finally determined according to the appropriate size of the packaging equipment.

- Is your FFS membrane applied in the market of powder or raw materials with significant proportion?

- At present, FFS film has become a mature packaging. Powder materials have been widely used in PVC paste resin powder and salt packaging.

- How do you solve the problem of easy unpacking after packaging?

- It can be solved by adjusting the formula to increase the friction coefficient.

- What are the requirements for the roll diameter of your FFS film?

- The size of the FFS film roll core can be satisfied by the packaging equipment. The bigger the better, this can save labor and reduce the time for changing the film roll. At present, the roll diameter of the mainstream equipment in China is normally about 1.35 meters. Adapt to size.

- What are the uses and characteristics of cold stretched film?

- Cold stretch sleeve film is suitable for packaging film of petrochemical, home appliances, building materials, bottle filling and other products, with excellent resilience, high clamping force to ensure stable load, excellent toughness, puncture resistance and resistance, good transparency, high It can maintain high-efficiency performance and other advantages in low temperature environment.

- What grades of modified raw materials can your polypropylene powder produce?

- Polypropylene powder can produce modified raw materials according to the needs of each customer, generally high and low melting index.

- What standard can the FFS film drop test achieve?

- Our FFS film drop test is better than the industry standard. If there are special requirements, our company can adjust the formula to meet the front 6 meters height drop.

- Are your FFS bags currently available?

- Our company currently has 3 imported FFS bag making machines, and the current daily production capacity can reach 80,000 pieces.

- What is the heat sealing temperature zone of FFS film?

- The heat sealing temperature is not the only constant, it is related to the ambient temperature, the newness of the welding knife of the packaging equipment, and the thickness of the film roll. Normally, the sealing temperature of our film roll is between 120°-180°.

- May I ask what is the reason for the poor sealing of the FFS film?

- There are many factors that affect the sealing of FFS film, such as dust at the sealing, dust, etc., the heating strip of the heat sealing equipment on the equipment is used for a long time, etc., and the silicon cloth on the heating strip is damaged, etc., which will affect the heat sealing effect of the packaging bag. It also depends on the situation on site.

- Why does the FFS roll film become soft in summer?

- Due to the high temperature in summer, the material of the film roll will be slightly softer than normal temperature when exposed to high temperature. If we need to improve this situation, we can adjust the raw material formula according to different temperatures and different regions to meet customer requirements.

- Our company just switched to FFS bags, can your company come to our company for on-site guidance?

- It is absolutely possible. Our company has professional FFS technicians who are familiar with the performance of FFS bags and the use of FFS packaging equipment. If customers need it, our company can arrange technicians to assist at any time.

- Why does the film roll become hard when the film roll is used to the middle, and whether it is affected by the use.

- In the production process of the film roll, it starts from the small roll to the large roll, so the force on the closer to the core will be greater, and it will be slightly harder than the outside of the film roll. Not affected.

- Why does the FFS film roll become hard when it is used to the middle part, and whether it is affected by the use.

- In the production process of the film roll, it starts from the small roll to the large roll, so the force on the closer to the core will be greater, and it will be slightly harder than the outside of the film roll. Not affected.

- What are the uses and characteristics of the cold stretched films produced by your company?

- Cold stretch sleeve film is suitable for packaging film of petrochemical, home appliances, building materials, bottle filling and other products, with excellent resilience, high clamping force to ensure stable load, excellent toughness, puncture resistance and resistance, good transparency, high It can maintain high-efficiency performance and other advantages in low temperature environment.

- Can FFS packaging materials be stacked after 1.5 tons?

- Yes, normally it is 1 ton for stacking. If you need to stack 1.5 tons, it is mainly to prevent the situation of loose stacking during production, storage and transportation. On the one hand, you can add a film on the outside. If you do not use a film, you can Increase the spraying of adhesive in front of the palletizer.

- What are the requirements for the roll diameter of FFS film?

- The size of the FFS film roll core can be satisfied by the packaging equipment. The bigger the better, this can save labor and reduce the roll change time of the film roll. At present, the roll diameter of the mainstream equipment in China is normally about 1.35 meters. In the end, according to the packaging equipment Adapt to size.

- Our company is going to use FFS film for automatic packaging. Can your company come to our company for on-site guidance?

- Our company is equipped with a professional technical team, who can go to the scene to give advice and guidance.

- Why does the current use of FFS film printing inks have color fading?

- At present, the printing ink of FFS film is mainly solvent-based ink. When encountering acid and alkaline substances in the packaging, when it comes into contact with its volatile gas for a long time, the color of the printing ink will be faded.

- What is the current speed of packaging plastic particles with FFS?

- At present, the high-speed FFS packaging machine can reach about 2000-2200 bags/hour, normally 25kg/bag, which is 50-55 tons/hour.

- Can your company produce food grade FFS film?

- Yes, our company has obtained a food packaging production license, and can also provide third-party inspection reports that meet food packaging.

- Irregular lines will appear on the film surface after the FFS film drop test, what is the situation?

- The material of FFS film is PE, and the stretch pattern left by the impact of the film surface after the PE film falls from a certain height, as long as the film surface is not broken, this is a normal situation.

- Our company is easy to loose after packaging with FFS film, what is the solution?

- It can be solved by adjusting the formula to increase the friction coefficient.

- Our company has just switched to FFS film packaging. Can your company arrange for technical personnel to come to the site for guidance?

- It is absolutely possible. Our company has professional FFS technicians who are familiar with the performance of FFS film products and the use of FFS packaging equipment. If customers need it, our company can arrange technicians to assist at any time

- Which industries can FFS film (bag) be used in?

- Heavy packaging bags can be applied to the packaging of fertilizers and other chemical products. In addition, the promulgation and implementation of the National Food Safety Law will further optimize food packaging. Specifically, it includes resins, industrial chemicals, compound fertilizers, special chemicals, cement, concrete, sand, mortar, lime, mortar, rice, sugar, flour, corn and other grains, as well as animal feed, agricultural seed production industries.

- Is it okay to purchase polypropylene powder before ordering without delivery?

- You can order first, but not pick up the goods for the time being. Our free warehouse period is 30 days.

- When our company uses FFS film to pack products, because there is dust on the surface of the bag, it is easy to be scattered after palletizing. Does your company have a solution?

- This situation can be improved by adjusting the formula to increase the coefficient of friction of the bag surface

- In addition to FFS Film and FFS bags, what other related products do you have in your FFS film project?

- At present, our company has 11 imported FFS bag film blowing machines, and can also produce cold stretch film, heat shrink film, tray pad film, etc

- what's the current capacity of your FFS Film?

- At present, our company has 11 imported FFS film blowing machines and 3 bag making machines, with an annual output of more than 30,000 tons of FFS Film.

- Why does the FFS film roll harden when its used in the middle part, and whether it has an impact on the use process

- in the production process, the film roll is rolled from small to large,so the force will be greater at the position closer to the roll core, which will be slightly harder than outside of the film roll, which has no impact on the use of the film roll.

- Why does the FFS film roll harden when its used in the middle part, and whether it has an impact on the use process

- in the production process, the film roll is rolled from small to large,so the force will be greater at the position closer to the roll core, which will be slightly harder than outside of the film roll, which has no impact on the use of the film roll.

- Can your current FFS film thickness meet the requirements of 0.14mm?

- of course we can, all the FFS film we supply to Sinopec have changed to the thickness of 0.14 mm

- How many sets of FFS film production equipment do your company have at present,and what is the annual production capacity?

- At present, our company have 11 imported FFS film production equipment with a production capacity of about 3000 tons/year.

- What is the reason for poor sealing of FFS film (bag)?

- There are many factors affecting the sealing of FFS film, such as dust and dust at the sealing place, long service time of the heating strip of the heat sealing equipment on the equipment, damage of the silicon cloth on the heating strip, etc., which will affect the heat sealing effect of the packaging bag. The specific situation depends on the site.

- Can you produce transparent FFS films? and what is the difference between transparent and milky white in price?

- It can produce transparent color, and the price is higher than that of milky white film

- Can your company produce the FFS film with transparent color instead of milky white? And what’s the difference between the price of them?

- Of course we can produce the transparent FFS film, but the price of it is higher than that of milk white film

- Do your company have a complete process and system for the control of FFS-film quality?

- of course we can do it, and we have a full set of inspection equipment. From the inspection of raw material,production process inspection to the delivery inspection of finished products, special personnel are responsible for tracking.

- Does your FFS film have any application in the market of powdery materials or raw materials with large proportion?

- At present, FFS film bag is a mature packaging. Powder material has been widely used in paste resin packaging and the raw materials with large proportion has been used in salt packaging.

- What is the implementation standard of FFS film?

- At present, there is no national standard for FFS film, and the industry standard BB/T 0058-2011 is implemented.

- The reason of FFS film seal is always broken

- There are three factors affecting heat sealing, temperature, time and sealing pressure. The above data need to be adjusted according to the actual situation.

- What methods can improve the strength and toughness of FFS film (bag)?

- By adjusting the production formula and increasing the thickness of the film (bag).

- Three functional characteristics of composite bags

- Three functional characteristics of composite bags First: Good overall performance. It has the performance of all the single-layer materials constituting the composite material, and the comprehensive performance is better than that of any single-layer material, which can meet the requirements of some special packaging, such as sterilization packaging under high temperature and high pressure, packaging with high barrier properties, and vacuum inflation Packaging etc. Second: The decorative packaging and printing effect is good, safe and hygienic. The printed decoration layer can be placed in the middle layer (the outer layer is a transparent material), which does not pollute the inner contents and plays a role of protection and beautification.

- Can your PE stretch film be produced now? What is the current production capacity?

- Can your PE stretch film be produced now? What is the current production capacity?It is possible. Our company currently produces 10 tons of PE stretch film per day.

- What is the current production capacity of your FFS film?

- What is the current production capacity of your FFS film?Our company currently has 11 imported FFS film blowing machines and 3 bag making machines, with an annual output of more than 30,000 tons of FFS film bags.

- What are the types of paper plastic composite bags?

- 1)A windowless bag is a bag without any windows on the composite paper. This kind of bag is opaque, and the contents of the bag can't be seen from the outside. 2) Strip window bag is also called strip window bag, that is, the bag with a transverse completely transparent window on the composite paper. The strip window of the bag is actually composed of two pieces of paper tape, one piece of plastic film and another wide plastic film. The bag is partially transparent, and the contents of the bag can be seen from the outside. 3) Special shaped window bag is a bag with irregular windows on the composite paper. This kind of irregular window is formed by die cutting on the paper tape in advance and then compounding. The bag is partially transparent, and the contents of the bag can be seen from the outside.

- Can the performance indexes of your FFS film meet the national standard?

- At present, there is only industry standard for FFS film, and all performance parameters of our products are better than industry standard.

- what methods can you improve the strength and toughness of your FFS film (bag)?

- at present, it can be improved by adjusting the formula and increasing the thickness of the film (bag).

- How can the FFS film (bag) avoid the dust left in the mouth when packing powdery materials?

- at present, this situation has been solved in the filling equipment. As long as the vacuum device is added to the equipment, the occurrence of this situation can be well improved.

- What is the reason for false sealing at the mouth and bottom of FFS film packaging?

- after FFS film packaging, sometimes the heat sealing line is good visually, but the actual situation is false welding. This situation often occurs when the packaging machine changes the coil. As the heat seal is heated by zones, the position of the film can not be adjusted in time after the film is changed. The avoidance: pay more attention to the opening of the machine after just changing the coil.

- How many FFS bags can you produce per day?

- at present, our company has 3 imported FFS bag making machines, and the daily output can reach 80000 pcs.

- What are the useage and characteristics of your cold stretch film?

- The cold stretched casing film is suitable for the packaging film of petrochemicals, home appliances, building materials, bottle filling and other products. It has excellent resilience, high clamping force to ensure stable load, excellent toughness, puncture resistance and resistance, and good transparency , It can maintain high-efficiency performance under high and low temperature environment.

- What are the advantages of FFS heavy packaging film (bag) produced by your company compared with ordinary woven bags in layout printing?

- FFS film (bag) has full color, clear writing, no color fading in printing, and the ink is environmentally friendly.

- How many FFS heavy coating production lines does your company have? How big is the production capacity?

- Our company currently has 8 imported three-layer co-extrusion blown film production lines, 3 printing production lines, and 2 FFS bag making production lines. The annual output of FFS heavy film is more than 20,000 tons. It is expected to import 3 more production lines in the second half of the year. , The annual output will reach more than 28,000 tons.

- Can FFS film use environmentally friendly ink?

- Yes, environmentally friendly water-based inks have been widely promoted.

- Is there any way to improve the strength and toughness of FFS film (bag)?

- You can adjust the production formula and increase the thickness of the film (bag).

- How does your company solve the problem of soft FFS film in summer?

- The material of the FFS film makes it feel soft to the touch in the high temperature in summer, but it does not affect the use, but if your company needs the bag to be stiffer, our company can solve it by adjusting the formula.

- Why does FFS film soften the film roll as the temperature warms?

- Due to the high temperature in summer, the material of the film roll will be slightly softer than normal temperature when the temperature is high. In this case, our company will adjust the raw material formula according to different temperatures and different regions to meet customer requirements.

- What is the width and thickness range of your FFS film?

- At present, the width of our FFS film roll is 420-650mm, and the thickness is 12-25 silk.

- What’s the capacity in the FFS bags currently produced by your company?

- Depending on the loading quality, the FFS bags currently produced by our company according to customer needs can be loaded with 10-50kg.

- What is the role of your FFS bag with M gusset?

- The FFS bag with M-folding will make the palletizing more beautiful, the palletizing height is higher, and the storage space will be saved.

- What is the thickness range of your FFS film?

- As for the current domestic packaging of 25kg/package FFS film, the thickness of 16 filaments is the mainstream state, but considering the reduction of packaging costs, the theory can be between 12-16 filaments. But it needs to be determined according to the material characteristics of the products installed by the customer and the environment in the region.

- Why is there a difference in the hardness of FFS membrane?

- Plastic film products will change with changes in temperature, soft in summer and hard in winter; but its quality will not change.

- What standards can FFS antistatic films meet

- By adjusting the formula of the FFS membrane, our company currently makes the membrane surface resistivity reach 10 to 10 ohms.

- How fast is the packaging speed of FFS heavy packaging film?

- According to the current domestic packaging situation of polypropylene / polyethylene packaging equipment, it is normally between 1600-2000 bales / hour. We choose to calculate based on 1800 bales / hour, which means that the packaging speed of one equipment is 45 tons / hour.

- Our company has just changed to FFS film packaging, may I ask your company to come to our company for on-site guidance

- Yes, our company has professional FFS technicians, who are familiar with the performance of FFS film products and the use of FFS packaging equipment. If customers need it, our company can arrange technical staff to assist at any time.

- Why does the FFS membrane become soft as the temperature warms?

- Because the high temperature in summer leads to high temperature of the film roll, the film roll will be slightly softer than normal temperature. In this case, our company will adjust the raw material formula according to different temperatures and different regions to meet customer requirements.

- During the use of FFS film, there are occasionally 1-2 bags with insufficient printing? What is the reason?

- This situation often occurs when the machine is stopped and changed or the stoppage time is longer. The ink on the printed anilox tube is dried due to the stoppage. If this is necessary for your company, we can mark the problem. The company can empty the bag when using it.

- What are the temperature characteristics of FFS film (bag)?

- It is heat-resistant and cold-resistant. It does not soften and deform in case of high temperature, and meets the requirements of 80 ° C high-temperature filling. It does not break and break in severe cold.

- Is the production requirements of FFS film(bag)strict?

- The heavy packaging forms in the domestic industrial field are mainly film covered woven bags, kraft plastic composite bags, kraft bags and FFS heavy duty films. The former three traditional forms can not meet the requirements of modern packaging due to their inherent limitations, so the application scope will be smaller and smaller. FFS heavy duty film will replace the traditional packaging and become the mainstream of heavy packaging field. Our company's FFS heavy-duty film is made of special polyolefin resin by multi-layer coextrusion process, and constantly develops and optimizes the product formula to provide good heat sealing and antifouling properties such as oxygen resistance, water resistance, light avoidance and antistatic, With higher tensile strength, impact resistance, puncture resistance and excellent sealing and moisture-proof performance, it can realize the perfect combination of product packaging quality and efficiency, meet the requirements of industrial high-speed packaging, and more in line with the national policy requirements of packaging safety, cost reduction and efficiency, energy conservation and environmental protection, it is the first choice of solid packaging products.

- After the FFS film is packed in stock, how to solve the problem of adsorbing dust on the bag surface in the warehouse?

- Allows FFS film manufacturers to add antistatic agents to their products to improve the adsorption of dust on the bag surface

- We use pp color film woven bag for packaging chemical fertilizer in our company. Can your company's FFS film be used for packaging fertilizer?

- Heavy duty packing film can be used for packing fertilizer and other chemical products.

- There is a sudden reversal phenomenon when using FFL film packaging. What is going on?

- First confirm whether it is the problem of FFS film. You can easily find the difference between the previous film rolls. If there is no difference from the previous film rolls, consider whether the raw material grade you switch contains slip agents. If In some cases, the manufacturer of the FFS film needs to adjust its raw material formula to increase the coefficient of friction on the surface of the bag;

- Which industries can FFS film (bag) be applied?

- Heavy packaging bags can be applied to the packaging of fertilizers and other chemical products. In addition, the promulgation and implementation of the National Food Safety Law will also promote the further optimization of food packaging. Specific examples include resins, industrial chemicals, compound fertilizers, specialty chemicals, cement, concrete, sand, mortar, lime, mortar, rice, sugar, flour, corn and other grains, as well as animal feed and agricultural seed production industries.

- What are the characteristics of FFS film (bag) compared with traditional packaging bag?

- Compared with the traditional packaging bag, the characteristics of FFS film (bag) mainly embody the following four points: 1. The formula of FFS film is special, which does not soften and deform in case of high temperature, and does not break in case of severe cold; 2. It is UV resistant and stable in color; 3. Compared with plastic woven bag, it can make the storage and shelf life of external packaging and internal products double; 4. Excellent sealing, moisture resistance, waterproof and antifouling performance. It can be stacked in the open air, convenient for transportation and storage. The internal products will not melt, agglomerate, lose quantity and lose quality.

- How many colors can your FFS heavy-film bag be printed?

- Four colors can be printed on the front and two colors can be printed on the back, which can help you design and optimize the layout, and the printing effect is beautiful.

- How high temperature can FFS film withstand?

- At present, by adjusting the formula, our FFS film can pack up materials with 90-110 degree.

- What are the advantages of your FFS film?

- Efficient and convenient loading, automatic continuous integrated packaging, convenient opening; safe storage and transportation; sealed, moisture-proof, waterproof, anti-fouling, can be stored in the open air; excellent high and low temperature resistance, prolong product storage and transportation time; puncture resistance, resistance to throwing Does not break the package; packaging stability is high.

- Can your FFS film be better than the industry standard in the drop test?

- Yes, we can adjust the formula according to the different requirements of each manufacturer. It can easily pass about 4 meters in the drop test, which is far better than the industry standard;

- How many FFS heavy production lines do you have?

- We currently have six imported three-layer co extrusion blown film production lines, with an annual production capacity of over 15000 tons. It is estimated that from the middle of 2020 to the end of 2020, we will introduce four imported three-layer co extrusion blown film production lines again, with an annual production capacity of over 25000 tons.

- How can you guarantee the timeliness and stability of logistics when shipping to remote areas?

- At present, our company has signed three logistics companies to supplement each other, and signed relevant service agreements for the guarantee of time and goods quality, so as to ensure the timeliness of delivery time and the integrity of product quality.

- What are the advantages of your FFS film compared with traditional packaging?

- Efficient and convenient loading, automatic and continuous packaging, convenient opening; safe storage and transportation; sealed, moisture-proof, waterproof, anti pollution, can be stored in the open air; excellent high and low temperature resistance, extended product time of storage and transportation; puncture resistance, anti throwing; high stability in packaging and stacking.

- Is the strength of your FFS film superior to the industry standard?

- Yes, we can adjust the formula according to the different requirements of each manufacturer, which is far superior to the industry standard;

- What are your company’s FFS film mainly used for packaging?

- At present, our company's FFS heavy packing is mainly concentrated in the petrochemical industry, and the packing contents are mainly resin particles and powdery chemical raw materials. There is a small amount of involvement in fertilizer and food industries.

- Your company can produce PE packaging bags. Can you produce pallet mat film?

- Yes. Please leave your contact information. Our company will arrange technicians to communicate with you.

- Q: How can FFS film (bag) avoid the dust left at the mouth of the bag when packing powdery materials?

- A: At present, this situation has been solved in the filling equipment. As long as the vacuum pumping device is added to the equipment, it can improve the occurrence of this situation.

- What is the packaging speed of the FFS film applied on the automatic packaging machine?

- At present, the speed of domestic automatic packaging machines is normally between 1600 and 2,200 bags/hour, and the conversion speed is 40-55 tons/hour.

- Is the FFS film currently used in the market for pp materials or larger density raw materials?

- At present, FFS films are already mature packaging, and powder materials are widely used in paste resin powders, which are widely used for salt packaging.

- Can the FFS film be able to withstand high temperatures of about 100 degrees when packaged?

- In principle, it is possible to achieve high temperature resistance by using high temperature resistant raw materials. Since there is no practical application in this aspect, it is necessary to carry out this test before the final conclusion can be made.

- What is the film surface resistance of the FFS film that can satisfy the friction of the film surface without generating static electricity?

- If the film surface friction is not to generate static electricity, the film surface resistivity should be at least 10 9 ohms;

- What is the diameter of the cold stretch film of your company?

- The normal diameter can be 95-100cm.

- Why does the FFS film also have a crack in the mouth after sealing?

- In this case, the temperature difference of the heating strip at the sealing part is generally fluctuated, and the heating strip is not replaced by the long-term replacement, resulting in no heat sealing of the mouth when sealing. This situation generally occurs as the fluctuation of the heating strip is reduced, or it can be normal with the heating strip.

- How to solve the problem that the FFS (film) bag has gas in the bag after packaging?

- At present, our company has the following methods in dealing with the FFS film (bag) packaged by the customer: 1. For the packaging material, it can not be in contact with the air, and can be vacuumed on the packaging machine; It is a fermentation product that can add a single exhaust valve to the package; 3. Exhaust in the form of micropores (small aperture); 4. Exhaust in the form of pinholes (slightly larger aperture).

- What is the production scale of your current FFS film?

- At present, our company has 6 FFS membrane imported blown film production lines with an annual supply capacity of 15,000 tons. In addition, our production capacity will increase to 20,000 tons/year by the end of the year.

- Why does the FFS film become soft in the summer?

- Because the high temperature in summer makes the film roll high temperature will cause the film roll to be slightly softer than normal temperature. If we need to improve this situation, we can adjust the raw material formula according to different temperature and different regions to meet the customer's requirements.

- Why does the FFS film stick to the roots?

- In this case, there is generally a high temperature in summer, the ambient temperature is high, and the film roll becomes soft, and the tension of winding near the root in the production winding process is greater. To improve the situation, it is necessary to change according to the temperature. Adjusting the formulation of the film roll can be improved;

- Can the FFS film make the film surfaces rub against each other without generating static electricity?

- It can be done, but everything is mutual. We can reduce the resistivity of the film surface by adding antistatic agent, so that the film surface friction does not generate static electricity. However, at the same time, as the antistatic dose increases, the friction coefficient of the film roll is drastically reduced. And this is the need to weigh the customer side.

- How does FFS film packaging reduce dust absorption during use and storage?

- We will add an antistatic agent to the film roll formulation during production to reduce the surface resistance of the film, thereby reducing the dust adsorption during packaging and storage.

- What is the shelf life of the materials in the FFS film (bag) compared to the traditional packaging?

- The formula of the packaging bag is special, it does not soften and deform when it is high temperature, it is not brittle and rupture in case of severe cold; it is UV-resistant and stable in color; compared with woven bags, it can double the storage and shelf life of outer packaging and internal products.

- Is the FFS film (bag) packaging capacity flexible?

- The packaging capacity is very flexible, and can be designed and manufactured according to the different requirements of different merchants for color, thickness and specifications, and can be adapted to the needs of different manufacturers and different regions.

- What are the advantages of FFS film (bag) in printing?

- FFS film (bag) printing according to customer's layout requirements, by adjusting the film through the film path, double-sided corona and multi-color printing. The printing line is generally equipped with embossing and folding device. The printed pattern of the product is clear and complete, the embossing force is suitable, and the side of the hem and the winding side are neat. The FFS heavy packaging film is based on the semi-finished film produced by the blown film line. The product is pre-formed by a series of facilities on the printing line to ensure the excellent heat-sealing performance, tensile properties and surface properties of the heavy-duty packaging film. Meet the requirements of customers in the use of the machine, palletizing, transportation and drop.

- Can your FFS film (bag) be customized?

- It is perfectly possible that the FFS film (bag) has a flexible packaging capacity and can be designed and manufactured according to the different requirements of different merchants for color, thickness and specifications, and can be adapted to the needs of different manufacturers and different regions.

- How is the FFS film (bag) print compared with traditional packaging?

- The surface of the FFS film (bag) is flat, smooth and beautiful. The printed pattern is rich in content, clear in color, and anti-counterfeiting. It is superior to the traditional packaging in all cases;

- What is the difference between FFS bags with M hem and without M hem?

- Because of the need of tray palletizing, the sides of the bag body are folded and processed, and the cross-section is shaped like M, which is good for palletizing;The sealing property without the M hem sealing is better than the M hem;

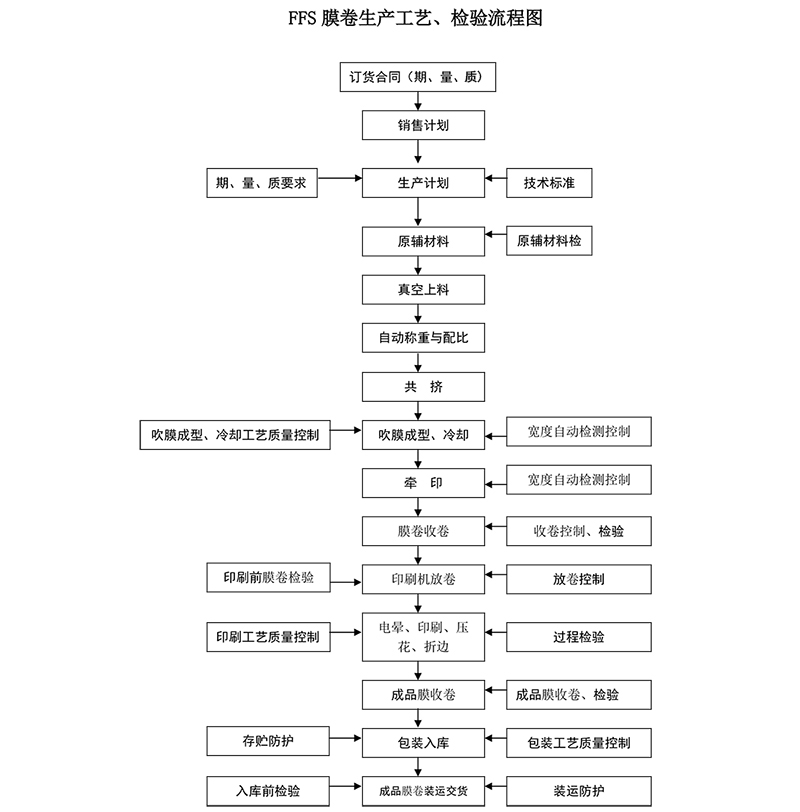

- What is the production equipment and process of FFS film?

- (Because the heavy packaging film not only needs strength assurance, but also takes into account the requirements of packaging, heat sealing, palletizing, transportation and other links, so the performance index is more complex, and it is difficult to meet the requirements by single-layer extrusion. The three-layer co-extrusion method can be used to decompose the quality indicators layer by layer, and meet the different quality indicators of customers through different film layers, so as to meet the requirements of the overall quality indicators. Therefore, the blown film line in the production of heavy packaging film is generally based on the international common three-layer co-extrusion pipe film process, with linear low density polyethylene as the main raw material. In the production process, the functionalization of thin films can be achieved by adjusting process parameters, interlayer ratio and raw material ratio. In the printing process, according to the customer's layout requirements, by adjusting the film penetration path, double-sided corona and multi-color printing can be realized. Printing line is usually equipped with embossing and folding device, which requires clear and complete printing pattern, suitable embossing intensity, neat folding and winding side. FFS heavy packaging film is based on semi-finished film produced by blown film line. Through a series of facility operation of printing line, bag pre-forming is realized, which ensures that the heavy pac...

- What are the advantages of FFS heavy duty packaging film over traditional packaging?

- The packaging automation is high, and the efficiency is 3-5 times higher than the traditional packaging; Excellent sealing, moisture, water and anti-fouling performance, can be stacked in the open air; Meet the filling requirements of high temperature materials below 80 °C; Excellent puncture resistance and drop resistance, effectively avoiding breakage; High palletizing stability for easy transportation and storage; In case of high temperature, it does not soften and deform, and it is not brittle and rupture in case of severe cold; Green, environmentally friendly, recycling, in line with national industrial policies;

- What is the FFS heavy duty packaging film?

- FFS heavy packaging film is an automatic forming potting bag: film (Film); filling (Fil1); sealing (Sea1) integration abbreviation, is the film online automatic forming - filling bag. It is different from the ordinary pre-made bag, after filling the contents, and then sealing the packaging method. There are two modes (vertical automatic filling and sealing) and (horizontal automatic filling and sealing).

- Can the FFS film (bag) pack 40kg material?

- Yes, the thickness of the film can be adjusted according to the variety and weight of the packaged material. The thickness of the normal 25kg film is 16 filaments, and the thickness of the film is 40 filaments or more.

- What is the current production capacity of your FFS heavy packaging film?

- At present, our company produces more than 15,000 tons of FFS film per year.

- I would like to ask the M-fold FFS bag after the installation of the exhaust valve, the sealing effect is not good, how is it?

- The purpose of installing the exhaust valve of the FFS bag is to single-exhaust, that is, the bag needs to be sealed after sealing, and the M-fold FFS bag is heat-sealed with 4 layers and 2 layers at the M-to-center connection. In this position, it is easy to cause unsealing; therefore, if an FFS bag is used to install the exhaust valve, it is recommended to use a one-shaped bag, not to use M-folded;

- What is the price of the FFS film compared to the traditional packaging bag?

- If the light is considered from the price, the price of the FFS film is only slightly higher than the traditional packaging. If the overall appearance, quality, packaging speed, labor cost, etc., the cost of the FFS film will be much better than the traditional packaging;

- Can you provide a third-party test report on plasticizer for FFS film?

- Yes, it can be provided.

- I would like to ask if the FFS film printing has faded, what is the cause?

- There is a major relationship between printing color and ink and film surface corona.

- Does the elongation at break of the FFS film need to be increased by the extension machine when it is tested by a tensile tester?

- It is not suitable to add an extension machine to detect items with relatively high elongation such as plastic film.

- I would like to ask that our company use only a few thousand bags a month. I want to use FFS bag packaging. Does your company know about sealing equipment?

- If the amount is not large, you can use a separate sealing device, such a device is around 6000 yuan! If you are interested, please contact me 18297599949 Liu

- How do FFS membranes (bags) avoid dents during finger handling?

- Because the FFS film bag is a plastic product, it is afraid of hooks and fears sharpness; it is suitable for the presence of dents in the fingers during handling; 1. The thickness of the FFS film (bag) can be increased to avoid, 2. Workers need to be involved in the loading process. Emphasize that you can't avoid it with your fingers.

- What is the advantage of FFS heavy film packaging compared to traditional packaging?

- FFS heavy packaging film has great advantages in labor cost and environmental protection, which is reflected in the advantages of fast packaging speed, one molding, no pollution, material saving, recyclability, low labor cost, good sealing moisture resistance and printing performance. status

- If the FFS bag is equipped with an exhaust valve, where is the best position on the bag surface?

- Without affecting the sealing, the position of the exhaust valve is about 15 cm from the mouth, and the lateral position can be on both sides or in the middle of the bag. The adjustment can be made according to the actual situation.

- FFS film (bag) has gas in the bag after packaging, how to solve the problem?

- At present, FFS membranes (bags) are available in four ways:1. For packaging materials, they should not be in contact with air, and vacuum treatment can be done on the packaging machine;2. For the content is a fermentation product, a single exhaust valve can be added to the packaging bag;3. Exhaust gas in the form of micropores (small pore size);4. Exhaust in the form of pinholes (slightly larger aperture).

- Why does the FFS film appear to be dropped when it is packaged?

- There are several factors, because it is the cursor detection, the color of the film is too transparent, which will cause the cursor to be easily detected, and the bag is soft, and the air pressure on the packaging machine is unstable. The aging of the suction cup will also cause this situation, specifically According to the situation on the spot.

- Our company has changed its valve pocket to FFS single bag. Can the original sealing equipment continue to be used?

- The sealing device does not need to be replaced. It only needs to be heated with the heating zone of the partition. The MFS of the FFS bag is 4 layers, and the middle is two layers. The temperature on both sides is higher than the middle temperature.

- What is the reason of the printing fade on the FFS film?

- There are two cases.1 The outer packaging should not be exposed to acid or alkaline substances, or stored in the air containing acid and alkali substances.2. If the first case is excluded, it is a problem of the printer or the ink.

- How is the FFS heavy duty film sealing?

- FFS heavy duty packaging film is excellent in sealing, moisture resistance, water resistance and antifouling performance. It can be stacked in the open air for transportation and storage. The inner product does not melt, does not agglomerate, does not lose weight, and the quality is not lost.

- I would like to ask my packaged products can not be in contact with the outside air, how to solve the problem of gas change after packaging with FFS bag?

- There are two ways. 1. If the product is similar to the type of fermented feed, the product will be continuously fermented to produce gas after packaging. This situation can be solved by adding a single exhaust valve. 2. If the product is packaged, it will not be fermented. It can't be in contact with the outside air, so it can only be vacuumed when it is loaded by the packaging equipment.

- Can you add a QR code to your FFS film bag?

- Yes,Of course

- Is the unit price of your FFS film is settled in tons or tons?

- Our film is settled at the tonnage price. If it is a single bag of FFS, it will be settled by piece.

- What is the temperature resistance of your FFS film printing ink?

- not exceeds 120 degree

- Is it difficult to open the FFS film when you use up to the core root?

- Our company will adopt a unique formula for the characteristics of raw materials used in FFS membranes to avoid the phenomenon that the root of the membrane can not be opened.

- When FFS heavy packaging film (bag) is used for packaging powder materials, does it affect the sealing effect?

- You can add a blowing gas before the sealing on the packaging machine equipment, which can completely prevent the powder material from sticking to the sealing part and affect the heat sealing effect.

- Can your company produce colorful FFS film bags?

- Yes. It can be produced.

- Can you provide a third-party authority inspection report for FFS film?

- Yes,we can

- Can your FFS film be used for fertilizer packaging?

- Yes. of course

- Can you produce sheet FFS film and cold stretch film?

- We can produce as customers’ request.

- What’s the size of ID of the FFS film core in your company

- The internal diameter of our film roll core is 150mm

- What’s the max FFS film thickness for your equirment?

- Our company imported blown film line, and the thickness range can be about 120 to 240 micron

- How does this three-layer co-extrusion blown film machine maintain the stability of each layer of raw materials?

- The three-layer co-extrusion blown film machine equipment adopts an automatic weighing and batching system, which effectively ensures the accuracy of the formula and the stability of the product quality.

- What are the advantages of FFS heavy-duty film in printing compared with ordinary woven bags?

- The FFS film is full-color in print, clear in writing, does not fade, and is environmentally friendly.

- What’s the role of side gusset with FFS heavy duty film(bag)?

- Side gusset will make the pallets more beautiful, the palletizing height will be higher, and the warehouse space will be saved.

- Will your FFS membrane bag be designed for labyrinth exhaust angle seals?

- It can be designed as a triangular or curved exhaust corner seal.

- If you use FFS anti-skid heavy-duty film for packaging, what is the maximum stacking height?

- You can stack 8-10 layers without M-folding and 12-15 layers with M-folding.

- How many kilograms of FFS heavy bags can your company currently produce?

- According to different loading quality, our company can produce 10-50kg different types of bags to meet the needs of customers.

- We need to pack 1,000 tons of solid particles. Consider packaging with FFS membrane. If it is a roll film, how many tons is needed?

- One ton of roll film can produce more than 7000 single bags, only 6 tons is enough for packaging.

- re:Can your company's FFS membranes hit the micro-holes in the folds?

- Q: Can your company's FFS membranes hit the micro-holes in the folds?A: The location of punch holes can be controlled according to customer requirements.

- Your company FFS film finished winding diameter of up to more than centimeter?

- A: Our FFS film is currently the largest winding diameter ≤ 150 cm.

- re: FFS questions?

- Q: What is your main raw material for FFS film production? A: The main metallocene, LLDPE, LDPE

- re:question: Your company FFS film printing layout in the automatic packaging machine can cut any guarantee can always have a complete page in the bag?

- question: Your company FFS film printing layout in the automatic packaging machine can cut any guarantee can always have a complete page in the bag? A: You can design cycle layout printing, can always ensure that there is a complete layout.

- re:What is the role of metallocene in your FFS membrane formula?

- What is the role of metallocene in your FFS membrane formula? A: It can enhance the toughness and tensile strength of the film, enhance the intensity of falling, so that the film can increase the anti-aging ability

- Can your company make a FFS maze maze bag?

- Answer: Yes

- What is the range of width and thickness of your FFS film?

- Hello! Our FFS film width range: 420-650mm, thickness range: 120-250 micron

- May I know, FFS equipments import from which country ?

- Italy and Germany

- re:can we use FFS bags ?

- Our company want to use FFS packaging bags ,how about the price of this kind of bags ? The price of this type bag is about RMB 2/PC, the confirmed price is based on the detailed specification, if you expect to cooperate, we want to serve for you.

- Do you produce food grade FFS film?

- We not only obtained the production license for Chemical product but also for food stuff. In full compliance with the state environmental requirements on food stuff.

- How many colors printing are workable at maximum?

- Four different colors on front side and two different colors on back side. Moreover, we can help optimize the design for more beautiful printing.

- What’s the thickness scope of FFS film?

- Thickness scope: 120-230 mircon.

- Can you produce the microporous FFS film? Does it affect the strength if hit micro hole?

- Yes,we can. Our equipment is equipped with the advanced micro hole-making device. No any influence on strength. Bag is not broken when dropping test.

Inspection Report

Production Process