Recommended Products

Film roll

This product is related to the product

Product Details

Product performance characteristics: (1) can withstand the following materials filling 70 ℃ and several handling turnover.

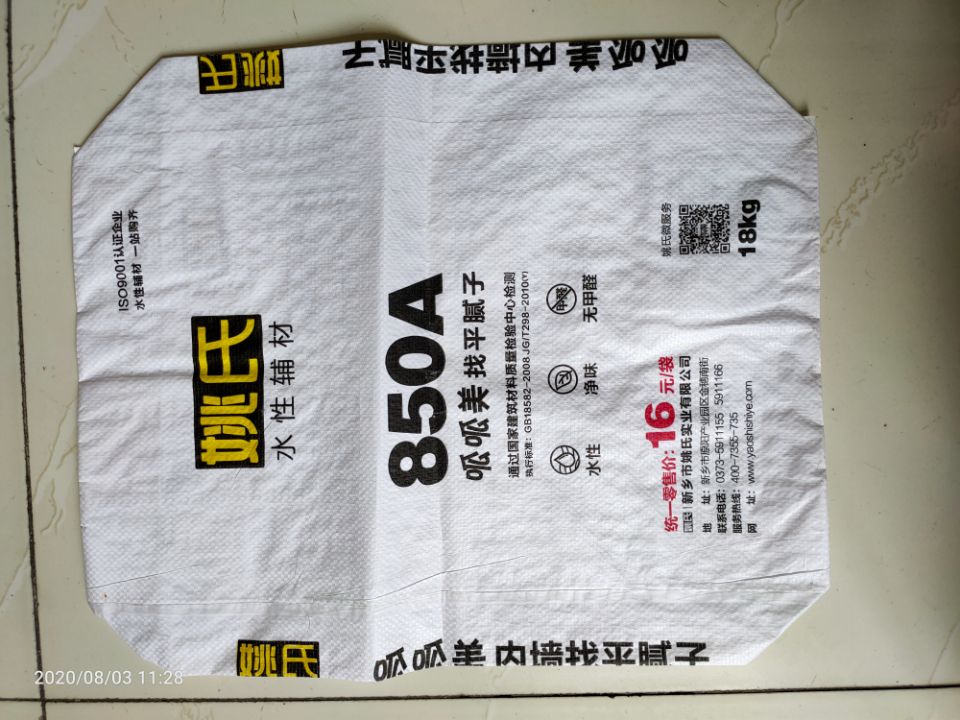

(2) bag surface smooth, bright and clean, beautiful, rich in pattern, color clear, and has security.

(3) sealing, moisture-proof, waterproof and anti-fouling superior performance, open-air stacking, easy to transport and storage, internal products do not melt, no caking, without loss of quality is not lost.

Anti-ultraviolet, color stability; compared with the woven bags, etc., can make the packaging and internal products, storage, shelf-life to extend the time to double the time, .

(5) flexible package capacity, for different businesses on the color, thickness, specifications, different requirements designed to suit different manufacturers and different regional needs.

(6) to improve packaging efficiency and reduce labor intensity. As the use of automated packaging forms, packaging speeds of 1200 ~ 2 000 bags / h, much higher than the traditional composite bag packaging efficiency, the number of operating workers by 70%.

(7) With the application of new materials, the film thickness gradually reduced, the intensity gradually increased, the overall cost of packaging is superior to traditional packaging.

(8) in line with national industrial policy, easy to deal with recycling, to maximize the protection of the ecological.

Advantages: FFS re-packaging film in the rapid packaging, a molding, non-polluting, saving materials, low labor costs, good sealing moisture and printing performance, etc. occupy a dominant position

FFS re-packaging film in China's application:

China's first introduction of FFS heavy packaging technology, due to lack of technical capacity and supporting facilities, the production of heavy packaging film quality is low, not enough to meet the heavy packaging requirements, so the Yangtze - BASF styrene series Co., Ltd. of polystyrene devices and Jinshan petrochemical polypropylene device on the use of domestic FFS heavy packaging film packaging synthetic resin, the packet rate is high, resulting in the bag outside had to add a woven bag, the production efficiency is low.

At present, the large-scale domestic enterprises have adopted this new packaging method in whole or in part, such as Sinopec (Yangzi Petrochemical, Qilu Petrochemical, Hainan Refining, Maoming Petrochemical, Zhenhai Refining, Tianjin Petrochemical, Wuhan Large Ethylene) Dushanzi Petrochemical, Lanzhou Petrochemical, Daqing Petrochemical, Fushun Petrochemical, etc.). In recent years, China's synthetic resin production growth rate has reached double digits. In 2005, the output of polyethylene and polypropylene reached 5.29 million tons and 5.23 million tons, an increase of 19.9% and 10.1% over the previous year. Most of these new production capacity comes from large-scale production of new production facilities, such as Shanghai SECCO in mid-2005 put into operation 600,000 t / a polyethylene, 250,000 t / a polypropylene and 300,000 t / a poly Styrene plant, Yangtze-BASF in early 2005 production of 400,000 t / a linear low-density polyethylene and high-density polyethylene plant, CSPC 450,000 t / a polyethylene and 240,000 t / a polypropylene plant, etc. [ 3]. All of these new devices use FFS packaging. Some old enterprises are also (or planning) to transform the original packaging line using the new high-speed packaging line, and even some non-resin products have begun to try to use FFS film packaging, such as paraformaldehyde and fertilizer packaging and rice cereal packaging .

At present, China's FFS re-packaging in the form of basic focus on the petrochemical industry, the main contents of the packaging resin particles, powdered chemical raw materials, fertilizer industry, a small amount involved. Of which 25 kg of resin packaging accounted for more than 90%. According to rough statistics, although the Sinopec system and the southern market more use of FFS heavy packaging, but look at the country, the overall market share of less than 20%, compared with Europe and the United States, there is still a big gap. In the next few years, with the expansion of the national ethylene and the vigor of the industry, FFS packaging will be more popularized in order to meet the needs of modern logistics and production.

International and domestic demand for packaging products: With the environmental protection and other aspects of the increasing demands of environmental protection, beautiful FFS re-packaging film homeopathic development, the potential is enormous. Since 2001, China's heavy-duty bag market with a number of new petrochemical enterprises put into operation and access to development opportunities. FFS re-packaging film to replace the traditional form of packaging has great potential.

(1) With the gradual progress of the country's large ethylene construction, there will be more petrochemical enterprises to use FFS packaging.

(2) three-tier co-extrusion technology to produce high-performance heavy packaging film of the mainstream processing technology.

(3) high-speed packaging line input and use, so that the market needs to match the more advanced packaging.

(4) In addition to resin packaging bags, heavy bags will be gradually applied to chemical fertilizers and other chemical products packaging, while the national "Food Safety Law" promulgated and implemented, will also promote the further optimization of food packaging. Specifically include the following industries:

Resin, industrial chemicals, compound fertilizer, specialty chemicals

B cement, concrete, sand, mortar, lime, mortar;

C rice, sugar, flour, corn and other grains;

D Animal feed, agricultural seeds.

The traditional form of packaging limitations: the traditional form of heavy packaging due to the existence of packaging material defects, directly limit its further development in the field of heavy packaging.

(1) Zhisu composite bags, paper bags need to consume a lot of paper, accelerating the consumption of forest resources;

(2) paper-plastic bag is difficult to recover, the environment pollution;

(3) paper-plastic bags easily lead to a large number of product loss and poor appearance;

(4) the appearance of plastic woven bags need to use benzene ink, does not meet the requirements of food safety law, thus restricting its use in the field of food packaging;

(5) the storage environment requirements, the need for moisture, anti-high / low temperature, must be stacked in the room;

(6) packaging speed is low, difficult to adapt to the packaging line of high-speed packaging requirements;

(7) production processes, labor and more labor-intensive, high labor costs.

With the gradual internationalization of China's heavy packaging market, China's packaging industry is facing more severe challenges and unprecedented opportunities, the use of more advanced forms of FFS packaging to achieve the form of heavy packaging replacement, will help improve the image of China's heavy packaging products, enhance International Competitiveness.